“Dharmaveer Sambhaji Maharaj Coastal Road”, built using advanced technology an engineering marvel.

To facilitate daily commuters, saving time and fuel, various infrastructure projects are underway across the country. India is striving to surpass developed nations’ highway infrastructure standards. The financial capital of India “MUMBAI” is growing on road infrastructure with pace of India’s growing transportation infrastructure. This shows the government’s clear intention to help the daily commuters and transport system to reach the destined place on faster time. This helps in reducing the overall fuel consumption and reducing carbon emission.

Also gone are those days when road infrastructure was only focused on concrete infrastructure. Now the highways are built not only for faster communication but also with various safety measures like digital signage, lane-driving safety indicator, surveillance system, real-time speed indicator and various other parameters connected through IP for real time action by authorities.

Due to availability of technology and expertise, now Indian road infrastructures are seeing growing demand of Tunnel to cut-down the length of the road. Utmost care has to be considered while having tunnel, and when it comes to first undersea Tunnel of India, between Worli and Marine Drive-in South Mumbai, India, Authorities were concern over every aspect including the circuit integrity of data flow happening through various systems at highest temperature and for longest possible duration.

Derwiser India Team, when informed about this project and its technical aspect of the cabling solutions requirements, challenges, implementation etc.,

Our technical solutions team had various communication with various team of team involved in this project for a cable which can be installed inside a tunnel and have connectivity for various application which should maintain the circuit integrity of data communication at:

- Fire survival cable at 950°C Temperature in accordance with IEC 60331-23:1999 standard.

- The fire survival capability should withstand at least for -180 minutes (about 3 hours).

- The un–interrupted voltage during critical period should be at least – 110 V.

- In a normal environment the application cable should be Anti-Termite.

- Due to installation requirements the cable should be Un-Armored.

- For high-end surveillance the cable should be POE Type4.

- To protect from noise and vibration cable should have Screen, Foiled sheathing.

Team Involved in Evaluation

- LARSON & TURBO LTD.

- AECOM INDIA PVT LTD.

- HONEYWELL AUTOMATION INDIA LTD.

- VAAAN INFRA PVT LTD.

- Other government & Project organizations.

Derwiser proposed its, DWC- 6ASM4L305GD – Cat6A S/FTP, Fire resistance data cable with all credentials and test reports, which were evaluated, verified by agencies, and were asked to have test witness at NABL accredited LAB prior dispatch, which our local team took up the challenges and supplied the cables, which is now installed and up & live.

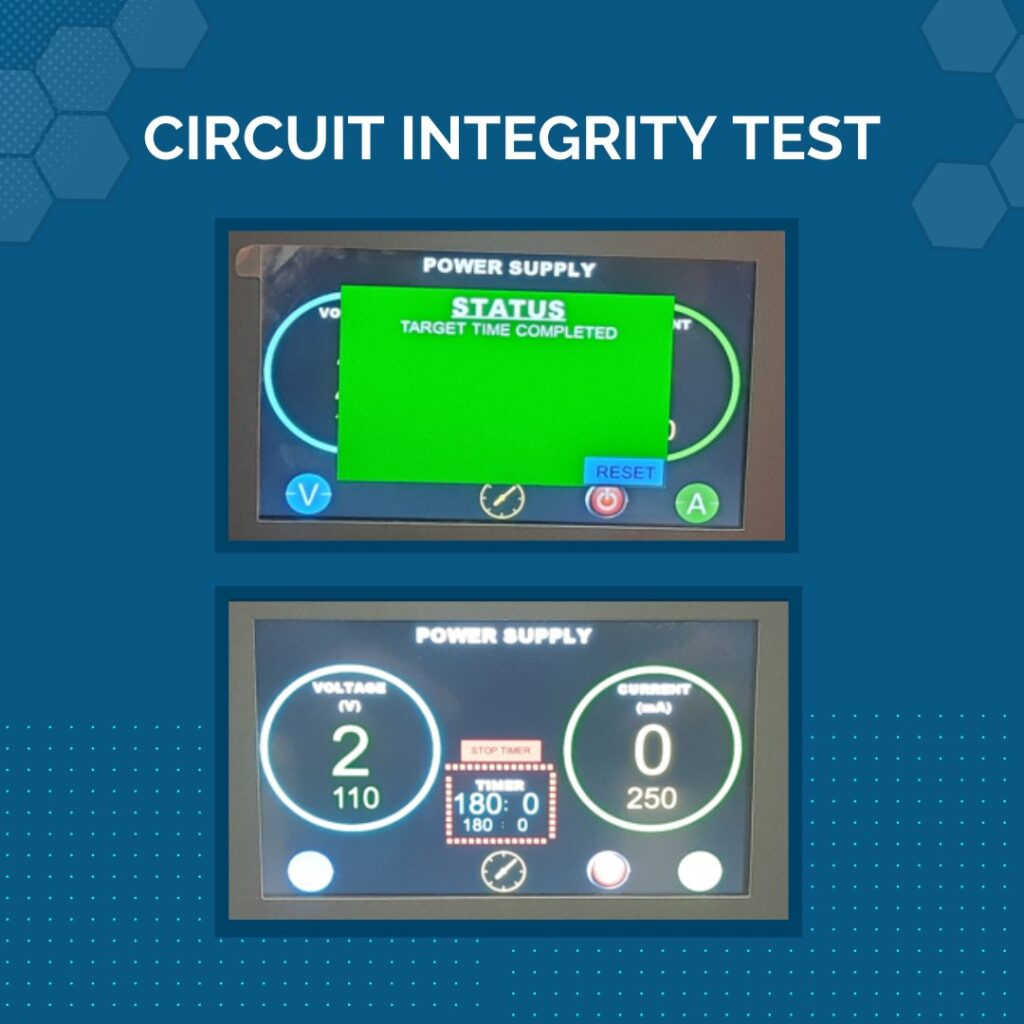

Test Bed at the Lab

The Result after 180 Minutes

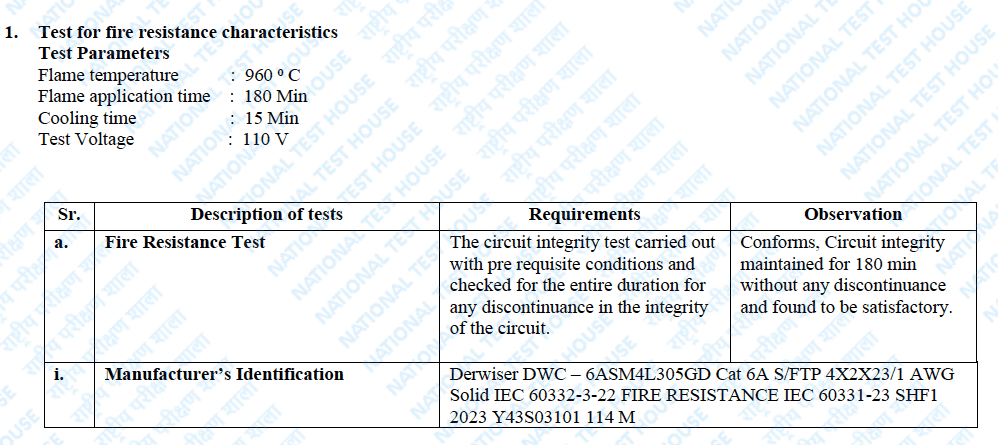

The Verdict after 180 Minutes (Extracts from the Final Certificate)

Results

The cable surpassed all expectations, confirming its excellence in withstanding extreme conditions and maintaining circuit integrity even in the face of fire.

Execution

Derwiser’s India team, confronted with this unique challenge, delivered the Derwiser Cat6A S/FTP 4 pair data cable, a fire-rated LSZH solid cable, meeting and exceeding RFP requirements. The cable underwent rigorous testing in front of the consultant and customer at the NABL accredited lab (National Test House, Mumbai, India), affirming its superior performance.

Conclusion

For IT networking in critical environments such as Manufacturing/Production, Oil & Gas, Tunnel Surveillance, or Fire-prone areas, Derwiser cables offer unparalleled infrastructure support. With their ability to meet and exceed the most stringent requirements, Derwiser cables are the top choice for data connectivity in demanding applications.